Loans for Food Manufacturers

Food manufacturing is a crucial industry for both consumers, restaurant and dining establishments. Having sufficient capital to run your food manufacturing facility is crucial to making sure operations run smoothly. In this article we will focus on the financial needs of food and beverage manufacturers, as well as all the loan options available to them.

Food preparation, production, and manufacturing has been essential for human survival since prehistoric ages. What was once done through salting, cooking, roasting, steaming, and oven baking foods, eventually evolved into modern food processing and manufacturing technology in the 19th and 20th century; this was developed largely in part to help with military needs. Through the development of a bottling technique known as “tinning”, the evolution of “canning” started and eventually became commonplace in American culture. After World War II, so many different types of food manufacturing processes had become essential when selling food to the rapidly growing consumer society, leading to what is now known as the food manufacturing business industry.

The food manufacturing business sector has seen increased demand for many changes throughout the industry, particularly with workforce standards. With many food manufacturing business owners working hard to improve workplace conditions, the food manufacturing business sector has seen slow but steady growth for employment throughout the food manufacturing business sector. This has led to increased profitability for many food processing businesses, particularly in the meat manufacturing sector. While meat manufacturing is the largest sector of food manufacturing, many other vital food manufacturing sectors follow it such as dairy, fruits and vegetables, bakery and tortilla products, seafood, beverages, and other foods.

The food manufacturing business sector has seen continuous growth, and will continue to expand as the overall population continues to grow. There is always a demand for food in such a densely populated world, but there are many different trends that are drastically shifting the food manufacturing business world.

Food Manufacturing Business Trends

- Innovation to Lower Costs: With any business, there are always companies exploring and searching for the most innovative new systems, practices, and technologies that can help drive down costs and increase productivity. For the food manufacturing business sector in particular, there are three key areas that have become a main focus for food manufacturing business owners everywhere: innovations that can help maintain profitability, new and innovative products to bring to the market, and modifications to product categories. With all of this in mind, the biggest component to these concerns is incorporating more cost effective means of doing these things, in addition to manufacturing, standardizing equipment, and automation to minimize labor costs (especially because the food manufacturing business world is still suffering from drastic labor shortages). Technology startups have become commonplace in the United States, and many food manufacturing business owners are constantly searching for better products. Today, many food manufacturing businesses are focusing on the profitability of a plant in all aspects, more so than ever before, all the way down to certain stock keeping units. Focusing on innovation is key in remaining profitable and competitive in the food manufacturing business sector.

- Going Green and Healthier, Natural Foods: Environmentally friendly and healthy solutions is a trend that is greatly shifting every single business in every food related industry. Consumers are valuing their health more than ever before, starting with reading ingredient labels, exploring where their food is coming from, and how their food is produced. In the United States today, endless amounts of people are starting to develop food allergies to many different foods (wheat/gluten, soy, corn, eggs, dairy, and so forth). This has led to many food manufacturing business owners being forced to implement safer cross contamination processes, as well as limiting the number and types of added preservatives and ingredients in order to reach a larger base of consumers. People are reading labels, and this reality has left many food processing companies struggling to adopt new practices. In addition to food safety and healthier food options and practices, consumers are demanding more energy efficient practices for businesses across the United States. While this transition can be incredibly expensive upfront, it will profit a food manufacturing company in the long run. Consumers are willing to spend the extra money to ensure that food manufacturing businesses everywhere are taking all the necessary steps to protect the environment.

- Refrigeration and Regulations: Over the years, the food manufacturing business sector has struggled with the implementation of new state and federal regulations in a variety of business areas; but the most problematic regulation that food manufacturing business owners everywhere are struggling with, and have been battling for a few years, is the new Occupation Safety and Health Administration’s (OSHA) new requirement for refrigeration systems. Since most industrial refrigeration systems that many food manufacturing business owners use cause damage to the atmosphere, food manufacturers are now required to phase out all old R-22 refrigerants and transition into more environmentally friendly options, such as CO2, by the year 2020. Food manufacturing business owners have been in the transition phase for a long time now, but many food manufacturing business owners are struggling to find an affordable alternative option. Through the use of food manufacturing business loans and food manufacturing business equipment financing, many food manufacturing business owners can find top of the line refrigeration systems that will meet OSHA guidelines and help to increase profitability by drawing in more consumers who are conscious of environmental efforts by food manufacturing businesses.

- Labor Shortages: The food manufacturing business has fought hard to battle the stigma associated with the work and employee environment. Typically, employees of the food manufacturing business sector endure long, strenuous hours of repetitive and physically demanding work in a dangerous, and sometimes toxic, work environment. A food manufacturing job often includes lifting heavy objects and using dangerous technologies that include cutting, slicing, grinding, packaging, and so forth. This has led to the food manufacturing workplace being one of the most dangerous jobs, with some of the highest work related accidents and injuries, in the United States today. This has led to major labor shortages in the food manufacturing business sector, but many food manufacturing business owners are working hard to improve workplace standards for all employees. If a food manufacturing business owner is willing to show changes in workplace environments, there may be an increase in people looking for jobs in this sector, which is why this has become such a vital transition for many food manufacturing businesses.

Food Manufacturing Bank Loans

Conventional business financing through a large or small bank, credit union or community lender is clearly the most affordable type of financing for food and beverage manufacturing companies. Rates for bank lending starts in the mid single digits and food manufacturers can expect to have longer terms, ranging anywhere from 3-30 years depending upon uses. Such uses that a food manufacturing company can use the financing for include purchasing commercial real estate, refinancing their food manufacturing facility into a lower rate, upgrades to the facility, purchasing business equipment and working capital.

Food Manufacturing SBA Loans

SBA loans are similar in rates and terms than those offered by large and small conventional banks because SBA financing for food manufacturing are loans provided by conventional lenders. The Small Business Administration doesn’t actually provide the loans to the food manufacturers but instead agrees to cover a large portion of the lender’s losses if the food manufacturer fails to repay their loan. SBA loans are used for business acquisitions, purchasing and refinancing commercial property, general operating capital uses, and purchasing manufacturing equipment and machinery.

Alternative Food Manufacturing Loans

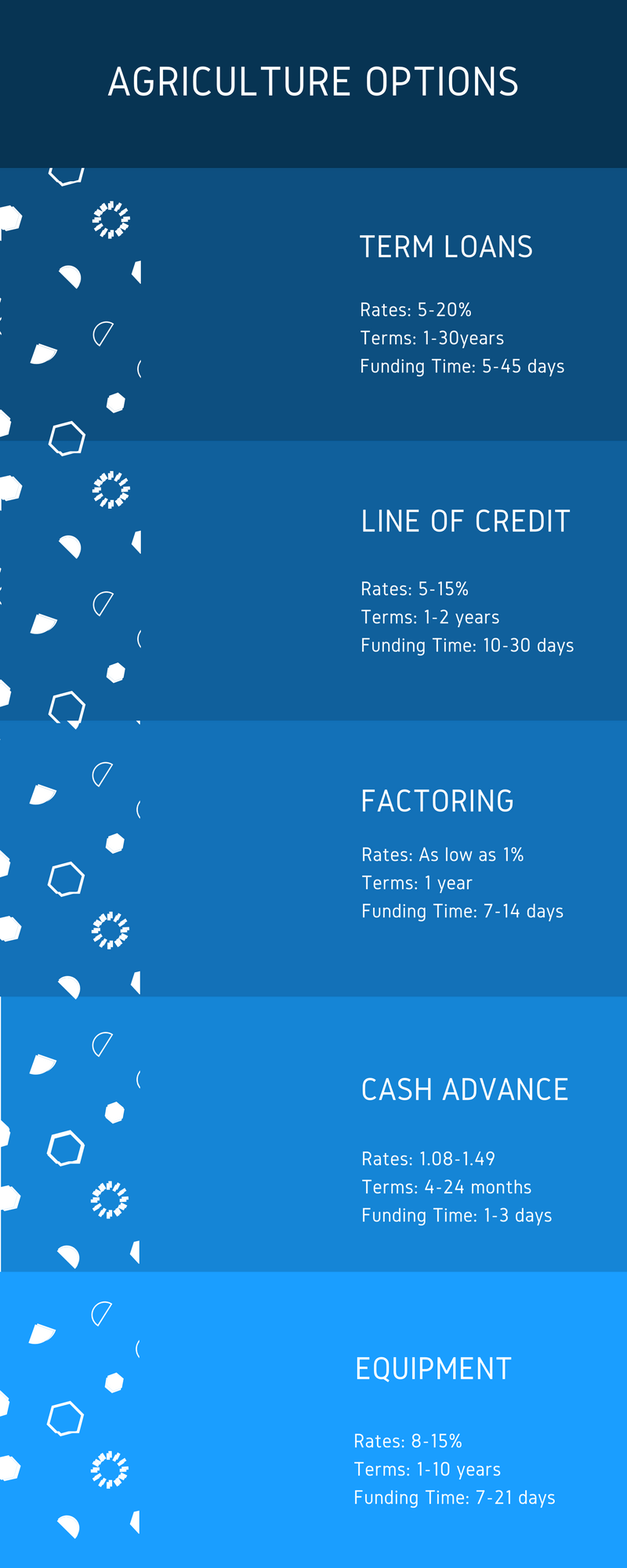

Alternative financing for food manufacturers are an easy way for small businesses to obtain working capital without the credit requirements, financial documentation, and net revenues required by conventional lenders. Within minutes of applying, the food manufacturer may receive preapproval, and funding can be completed in as little as one week. Since alternative loans are generally shorter in terms than conventional loans (usually between 1-5 years) alternative lending isn’t ideal for long-term business uses. Alternative loans are ideal for general working capital and cash flow to help with things like advertising, marketing, making payroll, expanding your business and other short-term funding uses.

Food Manufacturing Cash Advance

Cash advances for food manufacturing are ideal for small businesses in need of immediate short-term financing uses, without lots of paperwork required. Merchant cash advances are especially good for manufacturers with bad credit in need of capital, because cash advance lenders focus more on the business’s future revenue than they do on credit quality. This makes a MCA or ACH cash advance the perfect bad credit financing facility.